How to Choose the Right Stainless Steel Welding Rod

If you’ve ever welded stainless steel, you already know it behaves differently from mild steel. It’s tougher, less forgiving, and the wrong rod can easily ruin what should be a clean, strong weld. That’s why picking the right stainless steel welding rod isn’t just a small detail; it’s the foundation for weld strength, durability, and corrosion resistance.

So, how do you choose? Let’s break it down in a way that’s practical, not confusing.

Why Stainless Needs Its Own Rods

Stainless steel owes its durability to chromium, which forms a protective film that resists rust. But the same property also makes it tricky to weld. If you don’t use the right SS welding rod, you risk:

- Cracks forming under stress.

- Corrosion creeping in where you least expect it.

- Contamination that weakens the joint.

In short, the filler material has to “match up” with the base metal, or you’ll lose the very qualities that make stainless steel valuable.

What to Look at Before Picking a Rod

Choosing the best stainless welding rod comes down to a few real-world factors:

- The grade of stainless steel you’re working with – 304? 316? 409? Each has its own recommended filler.

- Where the weld will live – Will it face chemicals, seawater, or high heat? The environment dictates the rod.

- The type of job – Thin sheet metal needs low heat input; thick joints may demand stronger filler.

- Your process – Stick (SMAW), TIG or MIG your choice of process limits which rods make sense.

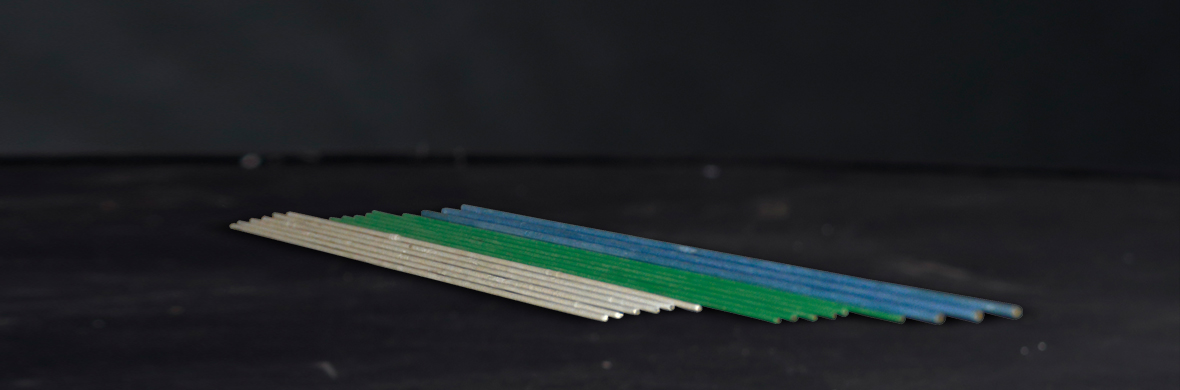

Ador’s Stainless Steel Welding Rod Range

Here are some of the main stainless steel electrodes available from Ador Welding:

| Product | AWS/Grade | Best Used For | Key Advantages |

|---|---|---|---|

| Superinox 1C | E308L-16 | Welding 304/304L stainless steels | Excellent corrosion resistance, low carbon reduces carbide precipitation |

| Betanox DL | E309L-16 | Welding stainless to carbon/mild steels, or stainless overlays | High strength, crack resistance, good performance for dissimilar welding. |

| Superinox 2C | E316L-16 | Welding 316/316L stainless steels | Superior resistance to chlorides and seawater; ideal for marine and chemical industries |

Matching Applications to Rods

- Food & Pharmaceutical Equipment → Superinox 1C (E308L-16)

- Joining Stainless to Mild Steel or High Heat Work → Betanox DL (E309L-16)

- Marine & Chemical Processing → Superinox 2C (E316L-16)

Tips from the Floor

- Keep your rods dry—moisture can cause porosity in the weld bead.

- Use proper shielding gas if you’re TIG or MIG welding.

- Watch your heat input—too much and stainless loses its corrosion resistance.

- Cleanliness is everything: dirt, oil, or even fingerprints can contaminate the weld.

Why Welders Prefer Ador

Ador Welding has provided stainless steel welding solutions for decades. Our rods are laboratory verified, and they have proven to work in the field for applications such as shipbuilding, oil & gas, chemical processing, and construction. What makes them stand out?

- Stable arc.

- Uniform weld appearance.

- Strong, corrosion-resistant joints.

- Technical knowledge and customer support.

Conclusion

The truth is, there’s no “one size fits all” stainless rod. The best choice depends on the grade of steel, the service conditions, and the job itself. Once you know those three things, picking the right rod gets a whole lot easier.

And if you’d rather not second-guess your choice, let Ador Welding guide you. From E308L to E316L and beyond, we’ve got rods engineered for real-world performance. Contact us to know more.

FAQs

1] What is the most commonly used stainless steel welding rod?

The E308L rod is the most widely used, especially for 304 and 304L stainless steels.

2] What is the difference between 308L and 309L stainless steel welding rods?

308L matches austenitic stainless steels like 304, while 309L is preferred when welding stainless to carbon steel.

3] What is the shelf life of stainless steel welding rods?

If kept dry and sealed, most rods last 2–3 years without losing performance.

4] How do you choose the right stainless steel welding rod?

Check the base metal grade, service conditions, and welding process before deciding.