Essential Steps for Successful Cast Iron Welding

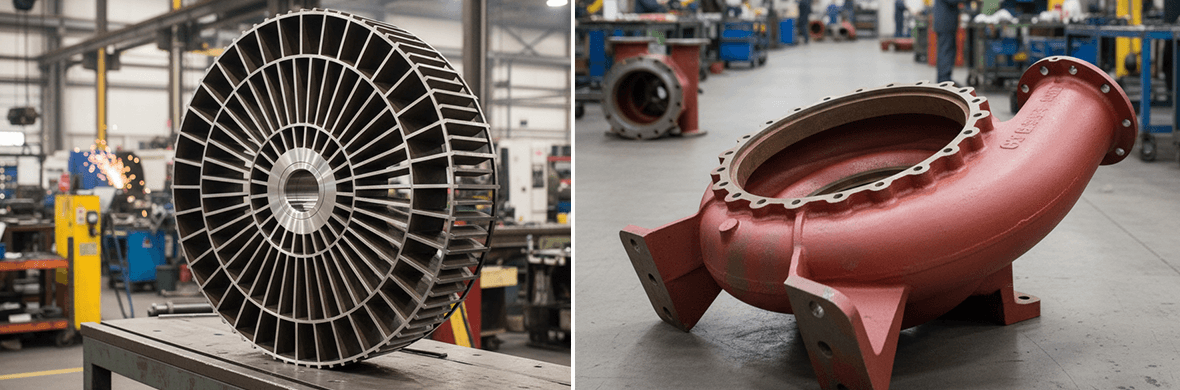

Cast iron appears to be a simple material at first – stiff, heavy, yet durable. But those who have attempted to weld cast iron know it can be complicated. Its own makeup, that is, what gives cast iron its strength and hardness, is what can make cast iron one of the most challenging metals to weld without cracking. But properly welded cast iron can save time, costs, and resources otherwise needed for replacements.

At Ador Welding, we’ve worked for decades to help industries repair instead of replace. This same philosophy is at the heart of how we engage in welding cast iron. Here is a closer look at the principles of doing it right.

Understanding Cast Iron: A Metal with Character

Cast iron isn’t one single material but a family of iron-based alloys. It typically contains 1.7% to 4.5% carbon, along with silicon (0.5–3%), manganese (0.2–1.3%), phosphorus (up to 0.8%), and sulfur (up to 0.2%).

The carbon content defines the type and properties of cast iron:

- A lower percentage forms hard, wear-resistant white cast iron.

- A higher percentage produces grey cast iron, known for its machinability and vibration damping.

Because of this versatility, cast iron is found everywhere — from engine blocks and pipes to machine bases and old industrial frames.

Distinctive Properties of Cast Iron

What makes cast iron useful also makes it tricky:

- Hardness: Naturally hard and can be further hardened by heating and quenching.

- Melting Point: Roughly 1200°C, which is lower than steel’s melting point of 1300-1400°C.

- Castability: The molten state of the material is fluid and can easily and quickly fill complicated molds, which is a notable benefit to manufacturing.

- Machinability: It tends to form short, brittle chips that will easily break off, giving it the advantage of smooth machining characteristics.

- Porosity: The many small pores in cast iron will hold a small amount of oil and grease, allowing for the best possible inherent self-lubrication, damping capacity, and utility in heavy machinery bases.

Types of Cast Iron Commonly Used

Cast iron is produced in several different grades depending on its carbon content and manufacturing process. Different grades will have different welding characteristics:

- Grey Cast Iron: Contains graphite flakes, which provide it with excellent machinability and vibration-damping characteristics.

- White Cast Iron: White cast iron is hard and brittle because of iron carbide in its structure, and is known for excellent wear resistance.

- Chilled Cast Iron: Chilled Cast iron is formed by rapid cooling, resulting in a hard, wear-resistant surface layer over a tough core.

- Nodular (Ductile) Cast Iron: Nodular (or Ductile) Cast Iron is ordinary cast iron that has spherical graphite nodules, which improve ductility, toughness, and impact strength.

- Malleable Cast Iron: Malleable cast iron is produced by heat treating white iron to obtain a cast iron that has good ductility and machinability to make small cast parts.

- Alloyed Cast Iron: Alloyed Cast Iron is produced by adding elements, such as nickel, chromium, or molybdenum, to improve strength, corrosion resistance, or heat performance.

Why Welding Cast Iron Is Difficult

Welding cast iron is not simply melting and joining metal together, but keeping control of what happens after the weld cools. Some of the most common challenges include:

- Brittleness: This leads to cracking, especially when subjected to rapid heating or cooling.

- Porosity and Contamination: The surface collects oil and dirt, which can be hard to remove.

- Excess Carbon: Excess carbon can cause cracking in the heat-affected zone during and/or after welding.

- Uneven Heat Transfer: This causes expansion and contraction in localized areas.

- Carbon Migration: Carbon concentration can develop in the weld pool, making the weld metal brittle.

The key to successful welding is to control heat and stresses, and this is where the process matters.

Two Established Welding Techniques for Cast Iron

There is no “one size fits all”. The selection of a methodology will depend on the type of job, the thickness, and the size of the part. In general, there are two methods: Hot Welding and Cold Welding.

1. Hot Welding Method

Hot welding is utilized for large or critical components, and where it is especially important to retain the integrity and strength of the component.

To hot weld, follow these steps:

- Slowly preheat the part to about 350–400 degrees C to prevent thermal shock.

- Weld at that temperature with the part always remaining at the same temperature.

- Cool the part slowly; turn the furnace off and allow the part to cool in open air. As a rule of thumb, you would like to keep the part cooling down in the range of 50 degrees C per hour for each inch of material thickness.

Why it works?

Because the part is steadily heated and cooled, you are able to avoid temperature changes to the material that create stress, and those stress changes are what cause cracking. Therefore, you will have a consistent, stress-free joint that is just as strong as the parent material.

2. Cold Welding Method

Cold welding can be used for smaller or repair jobs where the impracticality of preheating the entire parent component is not reasonable. In this case, the intention is to minimize the heat input as much as possible.

Practical guidelines:

- Use low amperage and smaller-diameter electrodes to keep heat low.

- Deposit only short, narrow stringer beads to avoid weaving.

- Keep the arc short, ideally less than the electrode diameter.

- Restrict each bead to 25–30 mm in length, allowing cooling between passes.

- Perform hot peening gently with a ball-peen hammer to relieve stress after each bead.

Why it works?

Cold welding causes minimal distortion and cracking since the weld area is small and stress levels are comparatively low, making it perfect for maintenance and field work.

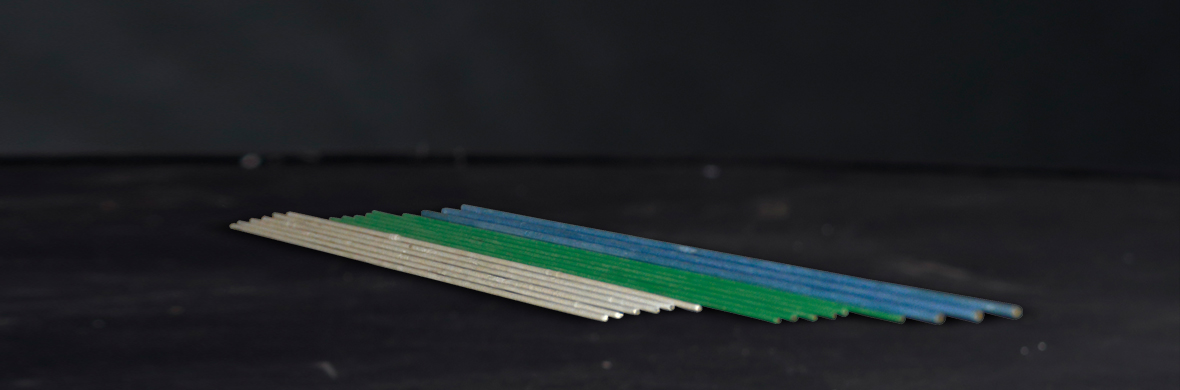

Electrode Selection – The Secret to a Good Weld

For all weldable grades of cast iron, nickel-based electrodes are the optimal choice. Both pure nickel and ferro-nickel work well, depending on the welding you are doing.

At Ador Welding, we have developed a specialized line of Low Heat Input Welding Electrodes for cast iron, which is designed to:

- Provide low heat input for low weld-induced stress.

- Increase machinability after the welding process.

- Work equally well for hot or cold techniques.

- Provide excellent crack resistance and durability.

In Summary

Welding cast iron is as much an art as it is a science. Its success relies on knowing the properties of the metal and having exact control over the heat input and the correct consumables. When practiced appropriately, cast iron welding can repair fabrication industries, conserve resources, and add life to machinery; precisely what “Reclaim, don’t replace” means.

When you partner with Ador Welding, you can trust your cast iron applications.

From foundries to maintenance shops, Ador Welding provides historically successful consumables, training, and experience to facilitate dependable repair and fabrication of cast iron.

If you are looking to enhance your welding operations or simply reduce rework and downtime, connect with Ador Welding. Our experts can help you choose the right electrodes, techniques, and parameters for every cast iron challenge — so your welds last as long as the machines they hold together.