Aluminum Brazing Rods for Automotive Applications

Walk through any modern car factory and you’ll notice one material everywhere – aluminum. Car manufacturers lean on it because it’s strong, resists rust, and trims vehicle weight. Less weight means better mileage and, for electric vehicles, longer range. That’s why you see it in radiators, AC units, and now in big structural parts like EV battery housings.

But aluminum comes with a headache: it’s not the easiest metal to join. Try welding thin aluminum sheets, and you risk burn-through or distortion. That’s where aluminum brazing rods earn their place. They let manufacturers and repair shops make strong, leak-tight joints without ever melting the base material.

So, What Are Aluminum Brazing Rods?

Think of them as a filler metal designed specifically for aluminum. Instead of turning the whole part molten, you heat just enough for the rod to flow and bond. The filler slips into the tiniest gaps by capillary action, and once it cools, you’ve got a sealed joint.

A few reasons they work so well in cars:

- They melt at lower temperatures (around 450–600°C).

- The flow is smooth, so they handle tight, complex shapes.

- They stand up to vibration, heat cycles, and constant exposure to fluids.

- They don’t corrode easily, even when in contact with coolant or road salt.

It’s a cleaner, more controlled process than welding when you’re dealing with delicate parts.

Brazing vs Welding – Not the Same Job

A lot of people outside the industry mix up brazing with welding. Here’s the real difference: welding fuses the actual base metals; brazing just melts the filler. That one distinction changes everything.

| Aspect | Brazing | Welding |

|---|---|---|

| Heat | 450–600°C | Above 660°C for aluminum |

| Base Metal | Stays solid | Base + filler both melt |

| Finish | Smooth, clean | Visible beads, may need grinding |

| Best For | Radiators, thin tubes, leak-proof joints | Load-bearing frames, thick parts |

| Distortion | Very low | Higher, especially on thin sheets |

If you’re sealing a radiator, brazing wins every time. If you’re building a car chassis, welding is your tool.

Why Brazing?

Here’s the thing: the automotive sector is under constant pressure to cut weight and improve efficiency. Brazing helps them tick both boxes.

- Weight savings: allows the use of thinner aluminum sections.

- Durability: joints don’t shake loose or crack under vibration.

- Better mileage: even saving 10 kg on a car can nudge fuel economy upwards.

- Lower costs: the process takes less energy and less time than welding.

Put simply, brazing has moved past being a backup option. It’s now a standard part of how engineers design and build cars.

Where Brazing Rods Show Up in Vehicles

If you pull apart a car and trace where aluminum joints matter most, you’ll keep running into brazing. A few stand-out areas include:

| Component | How Brazing Rods Contribute |

|---|---|

| Radiators & Heat Exchangers | They keep thin fins and tubes sealed tight so the cooling system doesn’t leak under pressure. |

| AC Systems | Used to bond condensers and evaporators where a reliable seal is non-negotiable. |

| Fuel Lines & Oil Coolers | Provide the kind of leak-proof joints that prevent costly failures. |

| Body Panels & Frames | Useful in lightweight designs and in day-to-day repair jobs. |

| EV Battery Housings | Offer strength and safety in the enclosures protecting modern battery packs. |

If any one of these joints failed, the entire system could go down. That’s why precision and reliability matter.

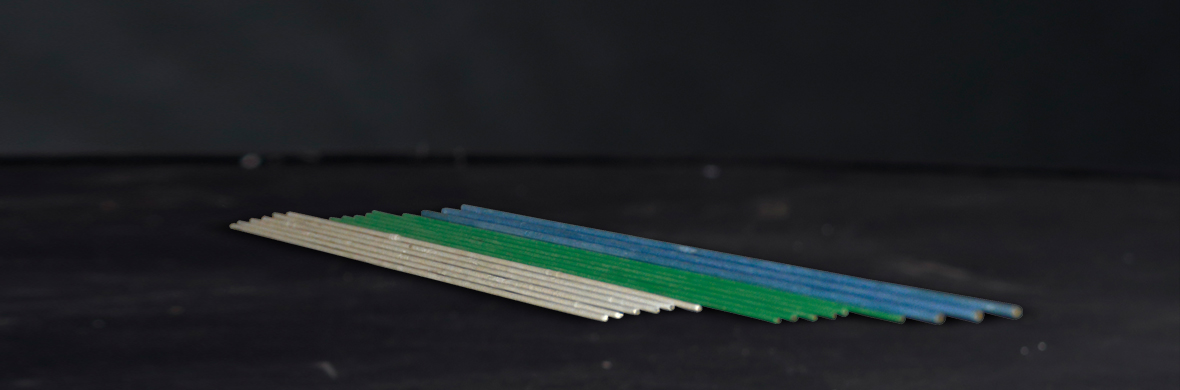

The Main Types of Brazing Rods

Not every rod works for every job, and mechanics usually keep a few options on hand:

- Aluminum–Silicon (Al-Si): The workhorse in radiators and condensers. Known for its clean flow and good corrosion resistance.

- Aluminum–Zinc (Al-Zn): Melts at slightly lower temperatures, which makes it easier to handle on thin parts or quick repair tasks.

- Aluminum Bronze: Less common in passenger cars but still useful in heavy equipment where extra toughness and wear resistance matter.

What Makes a Good Brazing Rod?

If you ask a technician, they’ll tell you the difference shows up in consistency. The best rods:

- Flow evenly without leaving gaps or pinholes.

- Hold up mechanically under stress.

- Resist corrosion from coolant, oil, or salt spray.

- Work reliably with different aluminum alloys.

That’s exactly what sets Ador Welding’s brazing rods apart, they’re engineered with the auto industry’s needs in mind, used both by OEMs and repair professionals.

Conclusion

Aluminum brazing rods don’t get headlines, but they’re one of the quiet backbones of automotive engineering. They make lighter cars possible, keep cooling systems sealed, and ensure EV batteries stay secure.

Ador Welding has built its range of aluminium brazing solutions to meet these real-world challenges. For anyone in automotive, whether you’re on the production floor or in a service bay, that means rods you can trust every single time.

Explore Ador Welding’s aluminum brazing solutions and see how they can strengthen your next automotive project.

FAQs

1] What are aluminum brazing rods?

They’re filler rods that melt at a lower temperature to bond aluminum parts without melting the base metal.

2] Why are they used in automotive applications?

Because they deliver strong, lightweight, and leak-proof joints in critical systems like radiators and AC units.

3] Can they repair radiators?

Yes, brazing is one of the most common ways to repair and manufacture radiators.

4] Do they work with all aluminum alloys?

Most rods are designed for broad compatibility, but the strongest results come when the filler matches the alloy closely.

5] What are the two main types?

Aluminum-Silicon (Al-Si) and Aluminum-Zinc (Al-Zn).