Arc Welding vs MIG Welding: Which One Should You Choose?

You might be trying to decide between an arc welding machine and a MIG welding setup.

It is probably because you’re trying to figure out what’s best for your project, what’s best for you, and of course, your budget and skill level.

Both welding methods use electricity and melt metals, but there are differences in technique, speed, and type of consumables or equipment used. Let’s take a look at the two methods to help you find the right solution for your needs.

Understanding the Difference: Arc vs MIG Welding

Arc (Stick) Welding:

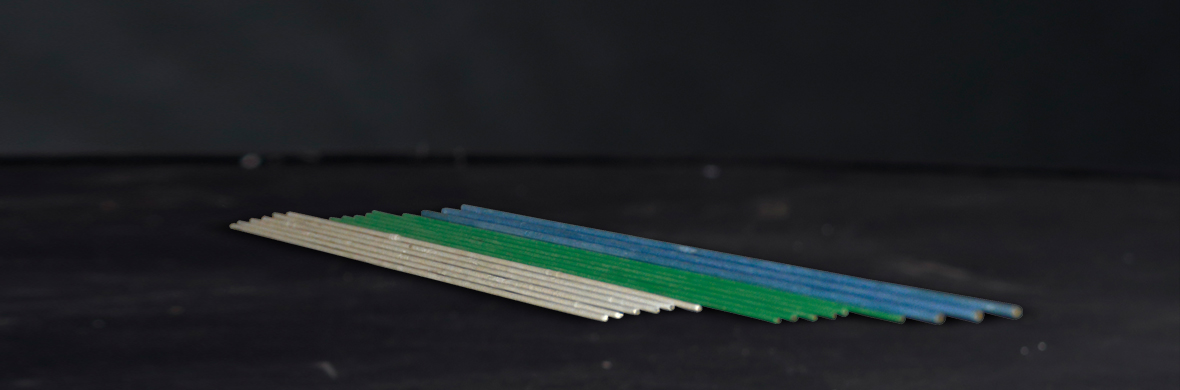

Also referred to as Shielded Metal-Arc Welding (SMAW), this welding process uses a coated electrode, or stick, that creates the arc and deposits the filler metal as it melts.

MIG Welding:

A MIG welding machine uses a continuous wire electrode feed through a motor-driven feeding unit. Weld Pool Protection is provided by shielding gas. An Arc is generated between a consumable electrode and the base material, creating a weld pool. So both arc welding and MIG welding use an arc welding machine, but there are differences in consumables and the workflow process, etc.

Key Comparisons: Arc vs MIG Welding

| Feature | Arc Welding (Stick) | MIG Welding |

|---|---|---|

| Equipment | Basic stick-electrode holder and CC power source. | MIG gun, wire feeder, gas supply, and CV MIG welder. |

| Consumables | Flux-coated rods. | Continuous wire and shielding gas. |

| Skill Level Required | HIGH, More hands-on; requires steady arc length and rod angle. | Moderate to Easier or more forgiving for beginners, easier control of the arc. |

| Performance Outdoors | Performs well, including in wind or unclean places. | Sensitive to wind and drafts (gas shielding). |

| Speed and Productivity | Slower; needs rod changes and slag removal. | Faster; smooth, continuous welds. |

| Maintenance Requirements | Minimal; just change rods and clean slag. | Requires regular gas and wire maintenance. |

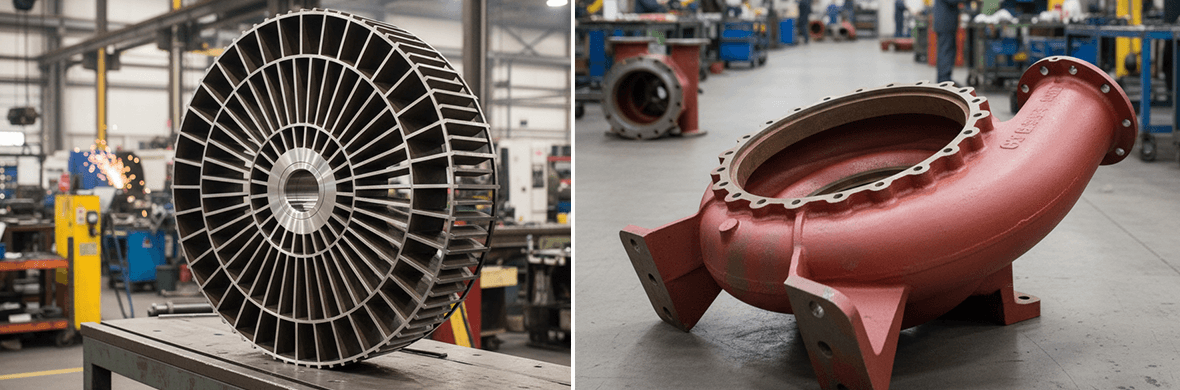

| Best Use Cases | Field repairs, heavy structural steel, rugged jobs. | Production, automotive fabrication, indoor shop work, and robotics. |

Which One Should You Choose?

Pick Arc Welding if you’re working outdoors, on structural or pipe welds, or in tough conditions without access to shielding gas.

Pick MIG Welding when speed, clean appearance, and indoor shop work are important-like in automotive bodywork or mass fabrication.

Conclusion

As part of choosing an arc welder welding machine, decide what matters most: rugged reliability or fast, clean output. Stick (arc) welding thrives in rough environments. MIG welding shines where production volume, ease of use, and appearance matter most.

Need help selecting a specific model or want a comparison chart breakout? Reach out to Ador Welding, and we will help you pick out the perfect welding machine!

FAQs

1] What is the main difference between arc welding and MIG welding?

Arc welding uses a flux-coated electrode that you feed manually, while MIG welding involves a continuously fed wire and gas shield for cleaner, faster welds.

2] Which welding type is better for outdoor use?

Arc welding is more reliable outdoors because the flux coating protects against wind and contaminants, unlike MIG welding’s gas shielding.

3] Which process is faster, arc or MIG welding?

MIG welding typically runs faster continuous wire feeding makes it more efficient for longer, uninterrupted welds.

4] What are the maintenance requirements for MIG vs arc welding?

Arc welding is low-maintenance (just swap rods and clean slag), while MIG welding needs regular checks for gas flow, wire feed, and nozzle cleanliness.

5] Which welding type is more efficient for production work?

MIG welding wins for production environments-its speed, cleaner finish, and consistent feed make it ideal for high-output work.