Five Mantras to Adopt Sustainable Welding

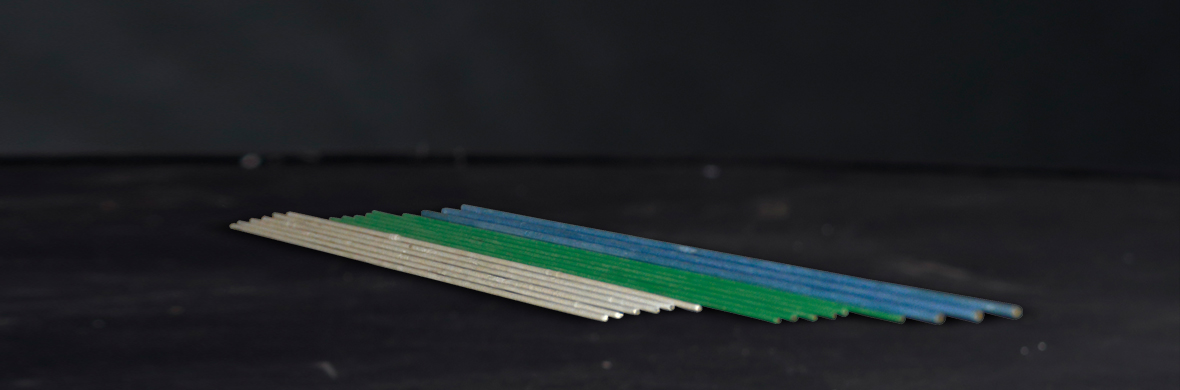

Welding holds the industry’s structure together. Out of the numerous joining methods available, arc welding, either Manual Metal Arc (MMA) or Shielded Metal Arc Welding (SMAW), is surely one of the oldest, most straightforward, and adaptable processes despite its rigor and energy consumption. If done intentionally, it can be an inherently sustainable process with long-lasting capabilities in both fabrication and repair.

At Ador, we believe that we all share the responsibility to apply sustainable welding applications for the benefit of both productivity and care for the environment. Here are five practical mantras to make arc welding genuinely greener, more efficient, and longer lasting.

1. Training: Build Skills the Smart Way

Welding is a craft. Good welds depend on muscle memory, eye-hand coordination, and an instinct for heat and filler. That makes practical training essential. But practical doesn’t have to mean wasteful. Modern training techniques such as Virtual Reality (VR) and Augmented Reality (AR) simulators are revolutionizing how welding skills are developed.

Use a layered approach:

- Start with short classroom sessions that focus on theory and safety.

- Add simulation-based practice (VR/AR, where available) to build technique without consuming consumables.

- Finish with supervised hands-on work on real joints so the trainee learns spatter control, placement, and finishing.

This combination shortens learning curves, reduces scrap, and produces welders who create right first-time joints, which can result in becoming the single biggest waste reducer in welding.

2. Welding Equipment: Choose Technology that Fosters Sustainability

The tool matters. Today’s digital inverters and microprocessor-controlled welders provide greater control over arc behavior, offer lower power consumption, and eliminate the need for rework. Ador Welding is part of the “Make in India” initiative to ensure welding equipment in India is sustainably produced.

- Equipment with digital parameter control to lock in repeatable settings.

- Energy-efficient inverters that deliver the same performance at a lower draw.

- Locally manufactured systems to reduce shipping emissions and speed service.

Such steps ensure that the equipment delivers consistent results, with the use of fewer electrodes, less filler, and less grinding, all of which lower material and energy waste.

3. Safety and Environment: Protect the Welder, Protect the Planet

A safe workshop is a productive workshop. Effective PPE and environmental controls are a component of sustainability because they reduce health risks, downtime, and defective work.

- Using helmets with auto-darkening filters, flame-resistant clothing, and comfortable gloves will help the welder work safely and efficiently over a longer period of time.

- Install effective fume extraction and ensure good ventilation; it protects health and reduces forced downtime.

- Maintain ergonomic stations to cut fatigue and the mistakes that follow.

Healthy welders are precise welders. And the reduced errors result in less waste, fewer repetitions, and a reduced carbon footprint.

4. Implementing Welding Processes: Start With the Right Intent

Sustainability is not just an accessory; it should be included in the welding procedure specification (WPS). Set goals and build them into the WPS:

- Define joint design, preheat, and interpass temperature limitations that prevent distortion and minimize rework after welding.

- Select consumables and wire sizes that reduce spatter and grinding.

- Define clear acceptance criteria so repairs are rarely subjective.

When the WPS is set up for efficiency and clarity, every job will run more cleanly, quickly, and benefit the whole shop.

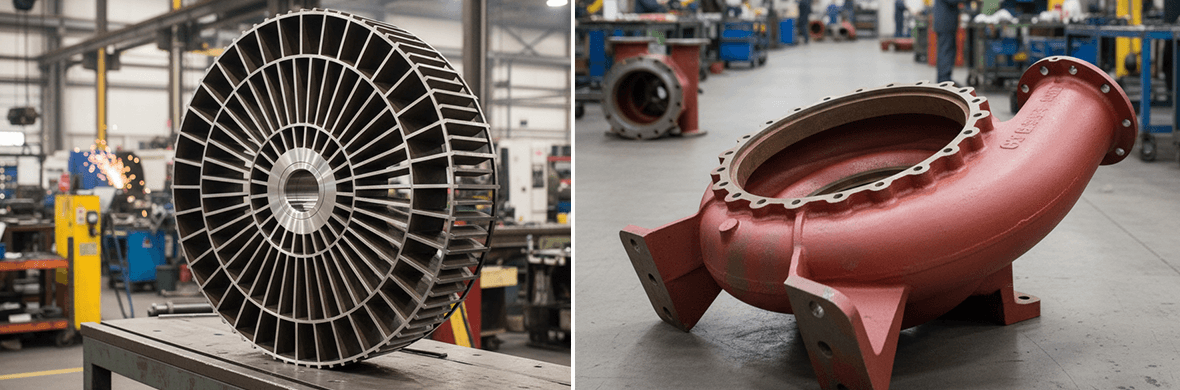

5. Reclaim — Don’t Replace

Perhaps the most powerful mantra of all — Reclaim, Don’t Replace. Ador Welding has been at the forefront of this mission by integrating this very motto for over four decades. All of our products are specifically designed to ensure the success of this mission.

Repair by welding is the heart of resource conservation. Rather than throwing away and purchasing new parts, consider whether welding restoration will safely restore function. Adopting a reclaim mindset means:

- Identifying components that can be rebuilt rather than replaced.

- Follow proper repair procedures to restore strength and geometry.

- Designing parts with future repairability in mind.

Restoring parts results in less material use, reductions in procurement, and is a step toward a circular manufacturing process. Reclaiming parts keeps materials in use, lowers procurement needs, and supports a circular approach to manufacturing.

Building a Greener Welding Future with Ador

As industries worldwide transition toward a low-carbon economy, the role of sustainable welding becomes ever more critical. From training welders responsibly to adopting digital technology, and from prioritizing safety to reclaiming materials, every step matters.

At Ador Welding, we are proud to lead this transformation — blending innovation with responsibility to ensure that every weld contributes to a stronger, safer, and more sustainable world.

Conclusion

Arc welding already offers a sustainability advantage because it supports repair and localized fabrication. But that advantage grows only when people, processes, and equipment are aligned around the same objective: do less, do it right, and keep things working longer.

Practical training, modern and local equipment, robust safety and ventilation, sustainability-oriented procedures, and a reclaiming mindset together make welding not just a production activity, but a resource-conserving one.

If you want welding practices that cut waste, save energy, and keep your assets working longer, Ador Welding can help.

From Indian-made, energy-efficient welding machines to tailored training programs and repair-centric solutions, we support shops that want to weld smarter.